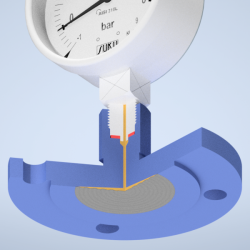

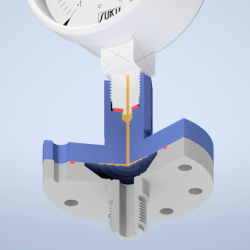

It is used to measure the pressure of liquids and gases if it is not possible for the measured medium to penetrate into the gauge or transmitter measuring device.

This need arises where they occur:

- Highly viscous liquids

- Solid particulate fluids, sedimentary sludge

- Hot liquids that solidify or crystallize when the temperature drops

- Aggressive fluids

- Requirements for perfect system cleanup

The solution consists in using a separating membrane and an inert liquid, that transfers pressure to the gauge or transducer measuring device.

We produce and repair many types of separators, different types of flanges and dimensions.

Gallery of chemical seals applications ...

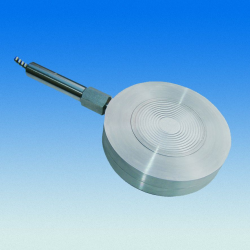

- Stainless steel

- Ranges from 60 kPa to 250 MPa

- illed with glycerine (optional)

- Bottom or rear connection

- Stainless steel manometers gauge DN63 or DN100

- Allows the use of large membrane properties at low attachment dimensions

- Connection: internal thread G1/2”, M20x1,5, NPT 1/2” (other subject to agreement)

- The separator can be dismantled and the interior space can be cleaned

- Tantalum membranes or PTFE protective films can be used to measure the pressure of aggressive chemicals; The bottom part can be made of durable plastic or a suitable lining.

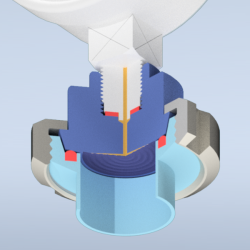

- connection with quick coupling with union nut according to DIN 11851

- conical neck (special design: threaded neck)

- dimensions DN: 25, 32, 40, 50

- used in the food industry

- also according to SMS, IDF and other standards

- The advantage of flanged separators (also called "open flanges") is the large dimension of the diaphragm, which is a prerequisite, for example, for accurately measuring lower pressures or for accurately measuring the pressure in the higher temperature range.

- Flange dimensions are according to ČSN 131160 resp. DIN 2501: DN25, 32, 40, 50, 65, 80, 100 (mm), possibly in inches according to ANSI 16,5.

- The advantage of a semi-sealed diaphragm flange separator is a relatively larger diaphragm with respect to the smaller attachment dimension

- Flange dimensions according to EN 1092-1: DN 15, 20, 25, 40 (mm)

- Flange dimensions according to ANSI B 16,5: DN ½“, ¾“, 1“

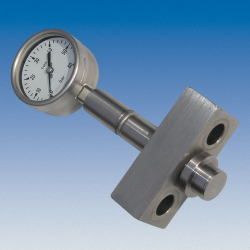

- It is used to effectively crush pressure because it allows the use of a very narrow throat cross section without the risk of clogging

- It is a simpler version of the K type separator.

- Connecting : G1/2”, M20x1,5, G1/4”, M12x1,5 according DIN 16288

- Body diameter: 40, 50, 60 mm

- The size of the diaphragm corresponds to the diameter of the body.

- Material: stainless steel (Monel, nickel, etc.)

- for water,air, hydraulic systems, petroleum products, chemicals, etc.

- also with diaphragm chemical seal

- hydrostatic level measurement

- analog or digital output ignal

- sanitizable design (CIP)

- explosion-proof design (ATEX)